4 min read

Forged to Perform: Reducing Downtime in High-Stress Fracking Applications

Southwest Steel Processing

:

May 12, 2025

Southwest Steel Processing

:

May 12, 2025

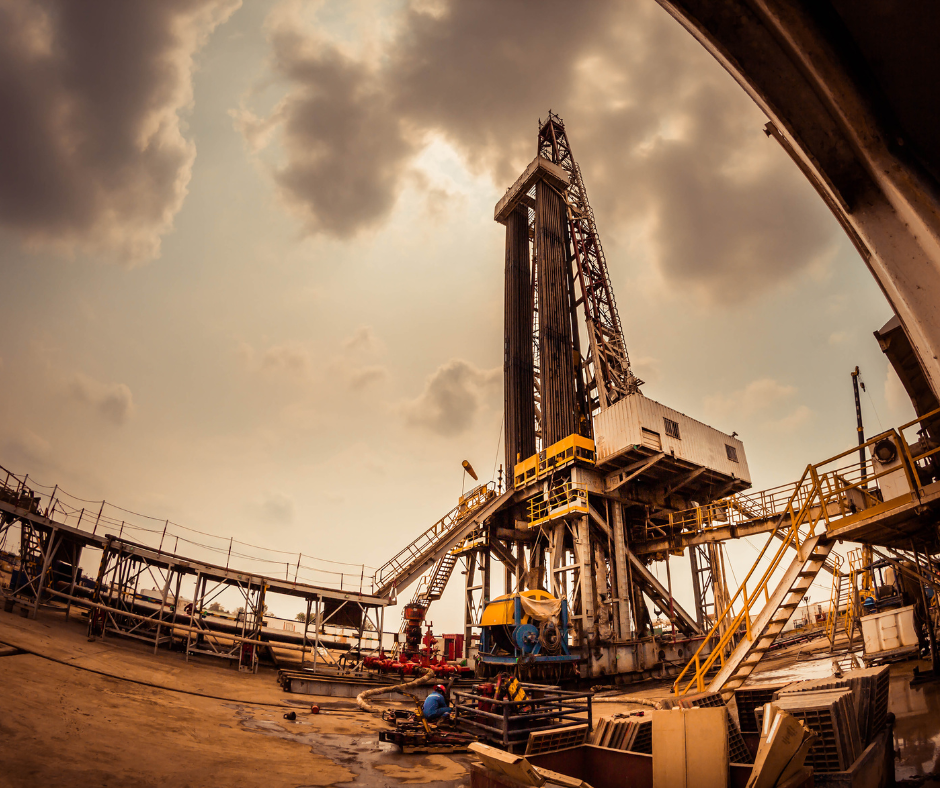

From fluid ends to frac iron, SSP’s forged solutions are engineered to withstand extreme pressure, abrasion, and vibration in the oilfield.

In the unforgiving world of hydraulic fracturing, uptime isn’t a luxury—it’s a necessity. Fracking operations are built around precise schedules, high-output targets, and massive capital investment. Every component in the system—from frac pumps and fluid ends to manifold connections and high-pressure fittings—must perform flawlessly under intense stress.

When even a single part fails, it doesn’t just disrupt production—it sets off a costly domino effect that can idle crews, delay well completions, and force expensive rescheduling of equipment and personnel. On average, each hour of unplanned downtime can cost anywhere from $1,000 to over $10,000, depending on the scope of the operation.

Unfortunately, many operators still rely on cast or low-quality components that simply weren’t built for the punishing environment of fracking. These parts are prone to cracking, accelerated wear, and unexpected failures—especially under cyclical loading, abrasive conditions, and extreme pressures. And when replacements are stuck in overseas shipping delays, downtime drags on, eroding profitability.

That’s where Southwest Steel Processing (SSP) steps in. As a domestic forging partner, SSP specializes in delivering high-strength, precision-forged components specifically engineered to stand up to the harsh demands of fracking. We help you reduce failure rates, shorten lead times, and increase operational reliability—so you can stay focused on extraction, not emergency repairs.

Why Downtime in Fracking Hurts More

In hydraulic fracturing, precision and timing are everything. Operations are meticulously planned, and any unexpected disruption can throw off entire schedules—resulting in delayed completions, strained contracts, and mounting costs. Fracking equipment is under constant, high-stress use, and when a component fails unexpectedly, it doesn’t just slow things down—it can grind the entire operation to a halt. For companies working in demanding regions like the Permian, Bakken, or Marcellus, the financial consequences escalate quickly.

Here’s what’s really at stake when a single part fails in the field:

- Missed Production Targets: Delays in the fracking schedule can push back deliverables, disrupt well plans, and result in significant losses in projected output.

- Idle Pressure Pumping Fleets: Multimillion-dollar equipment sits unused while crews wait on critical part replacements—burning through budgets without generating returns.

- Costly Crew & Equipment Rescheduling: When timelines shift unexpectedly, it leads to logistical nightmares—rescheduling frac spreads, equipment rentals, and personnel deployments.

- Emergency Repairs at a Premium: Last-minute fixes often require overnight shipping, emergency labor, or premium service calls—none of which are cheap or efficient.

- Lost Confidence & Contracts: Consistent downtime erodes operator trust and risks future contract renewals or service agreements.

And let’s not forget: many fracking sites are remote, with long lead times for replacement parts. That’s why it’s essential to work with a partner who not only delivers durability—but also understands the time-sensitive nature of your business.

To help operators stay ahead of failure points and avoid these costly scenarios, SSP offers a no-cost stocking program—ensuring that critical, high-wear components are available when and where you need them. By stocking parts in advance based on your project needs, we reduce your risk of downtime and increase your operational flexibility.

Learn more about our stocking services and other support programs here: SSP Services Overview

Built for Fracking Conditions: Why Forgings Outperform

Fracking isn’t just demanding—it’s punishing. Equipment is pushed to its mechanical limits, operating under extreme pressures, high flow rates, and continuous cyclic loading. Combine that with the constant assault of abrasive materials like sand and proppants, and you have a recipe for rapid wear and unpredictable failures—especially if you’re relying on low-grade, cast, or fabricated parts. In these environments, even the smallest weakness in a component can escalate into a catastrophic failure that halts operations and drives up costs.

At SSP, we engineer components to not only survive, but excel, in these hostile conditions. Our closed-die forged steel parts deliver superior mechanical properties, tighter grain structure, and greater structural integrity—making them ideal for high-pressure applications where failure simply isn’t an option.

Here’s how SSP’s forged components are built to outperform in fracking environments:

- Shock Resistance: Absorbs intense mechanical shock and sudden pressure surges in frac pumps without cracking or deforming.

- Wear Resistance: Withstands high-velocity flow of abrasive materials such as sand, chemicals, and proppants—maintaining performance over long runs.

- Toughness and Reliability: Performs in critical systems like fluid ends, manifold assemblies, power transmission units, and pressure control equipment—where component failure is not only expensive, but dangerous.

When downtime is measured in thousands of dollars per hour, you need components that hold up under the harshest conditions. That’s where SSP’s forged solutions deliver unmatched value—helping you reduce unplanned maintenance, extend equipment life, and protect your bottom line.

Avoid Supply Chain Bottlenecks with Domestic Production

In the fast-paced world of fracking, waiting on overseas shipments just isn’t an option. Global supply chain disruptions, port congestion, and international shipping delays can cripple project timelines—especially when your crews, equipment, and production goals are on the line. A missing part can delay a job by days, but a domestic, responsive manufacturing partner can keep everything moving forward.

That’s where SSP makes a measurable difference. Our components are 100% forged in the USA and a proven track record for fast, dependable turnaround. Whether you're replenishing high-wear frac iron for a rental fleet, replacing critical components during pump-down operations, or preparing for a multi-well pad completion, SSP ensures you get what you need—without the headaches of international freight, customs delays, or inconsistent lead times.

By choosing a U.S.-based forging partner, you gain:

- Shorter lead times that align with aggressive drilling schedules

- Greater control over logistics with reduced risk of transportation disruptions

- More consistent inventory planning thanks to reliable turnaround and just-in-time delivery

- Real-time communication and support from a domestic team that understands your industry

From planning to production to delivery, SSP eliminates the friction in your supply chain—so you can keep wells on schedule, crews on site, and profits on track.

Don’t Let a Cheap Part Cost You a Million-Dollar Well

Hydraulic fracturing is a high-capital, high-risk business. SSP helps reduce that risk by providing high-performance forged components that minimize failure points, extend equipment life, and support efficient project execution.

Protect your uptime. Protect your profits. Partner with SSP.

👉 Contact Us for a quote or to discuss custom solutions for your fracking operation.

.webp?width=460&height=66&name=logo%20(1).webp)