FORGING

When it comes to achieving unmatched quality in forgings, SSP is your ultimate solution. We specialize in forging high-volume, custom parts tailored precisely to your specifications, enabling you to deliver superior solutions to your customers. Unlike other manufacturers, we prioritize forging based on annual projections rather than purchase orders, ensuring consistent excellence in both quality and volume. When you require exceptional quality at scale, trust SSP to exceed your expectations.

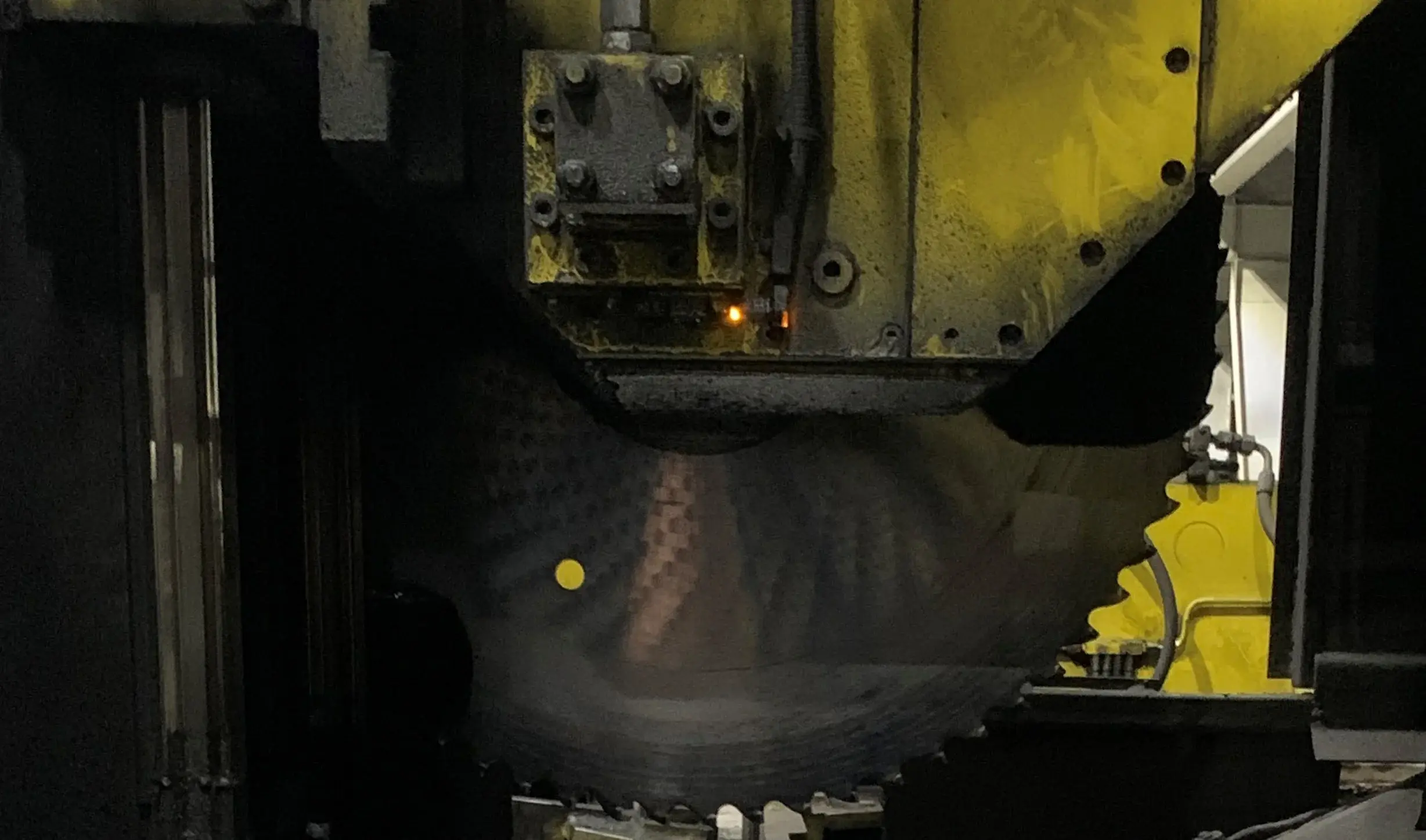

Forging Equipment: Utilizing the Best in the Market

At SSP, we rely on state-of-the-art forging presses provided by our esteemed sister company, Ajax/CECO/Erie Press. As the leading and most long-standing supplier of forging equipment in North America, they equip us with top-of-the-line machinery known for its superior performance and reliability. Our forging lines incorporate cutting-edge material handling robotic automation, guaranteeing consistent quality and enabling us to produce forgings weighing between 30 and 300 pounds. Witness our advanced equipment in action and experience the future of forging.

Custom Forging Capabilities:

Tailored Solutions for Optimal Results

Leveraging the expertise of our in-house engineering department, equipped with Solidworks 3D Modeling Software, SSP offers comprehensive forging services that bring your parts to completion. Our engineers design cost-efficient forging solutions, ensuring the lowest possible product cost while maintaining uncompromised quality. Count on SSP to transform your ideas into forged reality.

.webp?width=800&height=700&name=Southwest-Steel-Forging%20(1).webp)

.webp?width=800&height=701&name=Southwest-Steel-Forging-Capabilities-e1676912332596%20(1).webp)

CNC Cold Carbide Billet Sawing

Our automated metal cutting system, the CNC Cold Carbide Billet Sawing, surpasses standard production saws in both speed and productivity. It enables us to cut more parts per hour, using fewer blades. With this technology, we eliminate the risk of cold shear cracking, improve overall efficiency, and provide you with more competitive pricing. Experience the advantages of our cutting-edge cold carbide billet sawing for yourself.

The advantages of cold carbide billet sawing also include:

- Elimination of cold shear cracking

- Increased efficiency

- More competitive pricing

.jpg?width=870&height=500&name=Southwest-Steel-Services%20(2).jpg)

Shot Blasting

SSP offers on-site cleaning of your raw forgings using our advanced shot blasting equipment. Our Pangborn Rotary blaster and Rotoblast® Barrel Batch system ensure thorough batch cleaning and descaling, preparing your forgings for subsequent processes. Benefit from the effectiveness of our state-of-the-art shot blasting techniques and achieve optimal surface finish for your forgings.

Forging Advantages:

Uncompromised Quality for Critical Applications

When it comes to critical applications in the railroad, mining, industrial machinery, and gear industries, forgings outperform castings without compromise. At SSP, we understand the importance of quality, and our forgings deliver on every front:

Enhanced Strength

Our forging process creates a tighter grain structure, resulting in stronger end products.

Precision and Integrity

With forgings, you can expect products that maintain their intended form, exhibiting minimal porosity or cavities.

Structural Integrity

By reducing fabricating of multiple components, ensures fewer weak points, providing greater integrity.

Enhancing Mining Efficiency with Forged Components

Why Forged Components Outperform Casted Alternatives

In the demanding world of heavy machinery, the durability and reliability of your equipment are crucial to maintaining productivity and minimizing downtime. Forged components, such as teeth and track links, are built to withstand the toughest conditions, offering superior strength and longevity compared to casted alternatives. At Southwest Steel Processing (SSP), we specialize in producing high-quality forgings designed to enhance efficiency, reduce operating costs, and ensure your equipment performs at its best in any environment.

Quality Assurance

Our quality management systems meet international standards, which means we consistently provide products and services that fulfill customer and regulatory requirements.

ISO 9001:2015 Certified

AAR M-1003 Certified

American Association Railroads

ISO 14000

Compliant

Mitutoyo

FHM4CMM

Magnetic Particle

testing certified

Level three

PPAP capable

.webp?width=460&height=66&name=logo%20(1).webp)